Top Concrete Contractors: Reliable and Specialist Concrete Job

Top Concrete Contractors: Reliable and Specialist Concrete Job

Blog Article

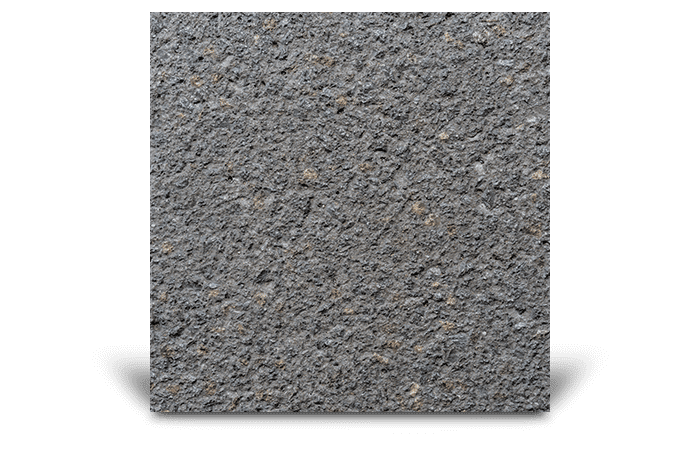

Unveiling the Eco-Friendly Advantages of Using Recycled Concrete in Sustainable Building Practices

In the world of lasting building techniques, the use of recycled concrete stands as a critical yet often underestimated resource. Past its traditional applications, recycled concrete deals a myriad of environment-friendly benefits that expand far past the boundaries of standard construction products.

Environmental Advantages

By integrating recycled concrete right into building practices, there is a significant reduction in the need for brand-new raw materials, leading to preservation of natural resources. Additionally, the usage of recycled concrete diminishes the quantity of waste being sent out to land fills, consequently reducing ecological pollution and easing the pressure on garbage dump capacities (Concrete).

Furthermore, the production of traditional concrete is a significant resource of carbon discharges because of the energy-intensive procedure of concrete production. On the other hand, recycled concrete has a reduced carbon impact as it minimizes the need for new concrete production. This decline in carbon discharges adds to mitigating environment change and sustains sustainable construction techniques. On the whole, the ecological benefits of making use of recycled concrete are considerable and play a critical function in promoting eco-friendly building and construction approaches.

Cost-Efficiency

When evaluating the application of recycled concrete in construction tasks,Achieving cost-efficiency is an extremely important consideration. Among the key advantages of making use of recycled concrete is its cost-effectiveness compared to typical concrete. The production of recycled concrete includes much less power and sources as it makes use of existing materials, minimizing the total project costs significantly. Furthermore, the schedule of recycled concrete locally can even more reduce transport expenses, making it a much more cost-effective selection for construction projects.

In addition, making use of recycled concrete can bring about savings in landfill costs by drawing away concrete waste from disposal websites. This not just lowers the ecological influence but likewise gets rid of the expenses connected with waste removal. Moreover, the longevity and performance of recycled concrete approach traditional concrete, making sure that price savings do not endanger the quality of the building.

Longevity and Toughness

Recycled concrete deals similar, if not superior, sturdiness and strength buildings to standard concrete - Concrete. Through developments in handling strategies and top quality control, recycled concrete can meet or surpass the efficiency requirements of traditional concrete.

Waste Decrease

When it comes to making use of recycled concrete, waste decrease is an essential advantage that adds substantially to ecological conservation. By incorporating recycled concrete into construction projects, this waste is repurposed and drawn away from land fills, minimizing the general environmental influence of building tasks.

Furthermore, the usage of recycled concrete can lead to cost financial savings for building projects, as it is commonly more economical than sourcing and moving new products - Concrete. In verdict, waste reduction with the application of recycled concrete is a crucial part of sustainable building methods that profits both the environment and the building and construction industry as a whole.

Energy Conservation

Power conservation is an important facet of lasting construction methods, intending to lower the overall energy consumption related to structure operations and materials manufacturing. When it comes to using recycled check concrete in construction, considerable power financial savings are attained contrasted to standard concrete production. The process of creating recycled concrete involves crushing and reusing existing concrete products, which eats much less power than mining, handling, and moving raw products for brand-new concrete production. Additionally, the use of recycled concrete can assist decrease the demand for virgin accumulation, additional minimizing the energy-intensive removal and handling of all-natural resources.

Final Thought

In conclusion, the application of recycled concrete in sustainable building and construction techniques uses various ecological benefits, cost-efficiency, resilience, stamina, waste reduction, and power preservation. By incorporating recycled concrete right into construction projects, we can add to a much more eco-friendly and sustainable future. It is vital for the construction industry to prioritize making use of recycled materials to help in reducing the ecological impact of building and construction activities.

One of the essential benefits of utilizing recycled concrete is its cost-effectiveness contrasted to traditional concrete.Additionally, the use of recycled concrete can lead to financial savings in garbage dump prices by diverting concrete waste from disposal sites. The longevity and performance of recycled concrete are comparable to traditional concrete, guaranteeing that price financial savings do not endanger the high quality of the building and construction.

Report this page